Our Factory

From material selecting to goods shipment, each step reflects our commitment to quality and innovation.

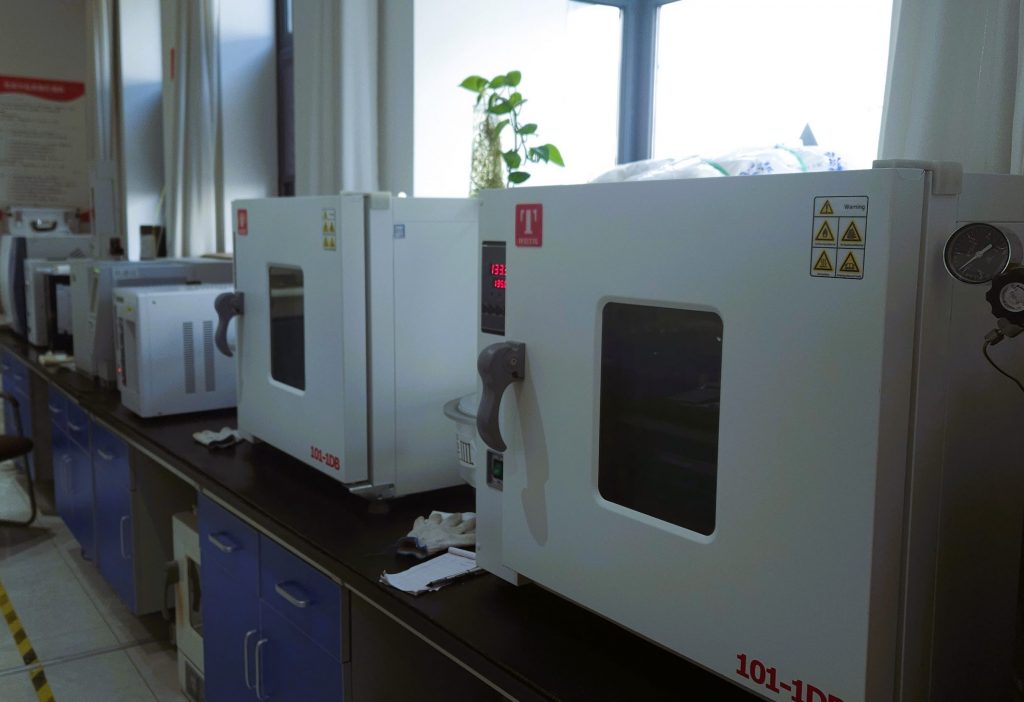

Factory's views

Our factory specializes in Hydroxypropyl Methylcellulose (HPMC) production for construction, pharmaceuticals, food, and industrial applications. With advanced manufacturing technology, strict quality control (ISO, GMP certified), and eco-friendly processes, we ensure high-purity, high-performance HPMC for global markets.

Key Applications:

✔ Construction – Tile adhesives, mortars, coatings

✔ Pharmaceuticals – Binders, film coatings, controlled release

✔ Food & Personal Care – Thickeners, stabilizers, emulsifiers

✔ Industrial Uses – Paints, detergents, polymer processing

We are committed to quality, innovation, and sustainability, delivering reliable solutions worldwide. Contact us for inquiries.

Storage & Shipment overview

Our factory is equipped with an efficient inventory management system, secure storage facilities, and a streamlined shipment process to ensure the timely supply of high-quality HPMC products worldwide.

1. Inventory Management

✔ Large-scale stock capacity to meet bulk and customized orders.

✔ Strict quality control ensures product integrity from raw materials to finished goods.

✔ Real-time tracking system for accurate stock levels and efficient order processing.

2. Storage Facilities

✔ Well-ventilated warehouses to protect products from moisture and contamination.

✔ Secure and organized shelving for quick access and optimized space utilization.

✔ Temperature and humidity control for product stability and longevity.

3. Shipment & Loading

✔ Automated packing and labeling for accurate order fulfillment.

✔ Multiple transportation options (container, bulk shipment, express delivery) for flexible logistics.

✔ Dedicated loading zones to ensure fast, safe, and efficient truck and container loading.

With a robust supply chain and global distribution network, we guarantee on-time delivery and consistent product availability for our customers.

Quality Control & Assurance

At our HPMC manufacturing facility, we uphold the highest quality control standards to ensure purity, consistency, and performance in every batch. Our ISO-certified processes and strict testing protocols guarantee that our products meet international industry standards.

1. Raw Material Inspection

✔ Sourced from high-purity natural cellulose, rigorously tested for contaminants.

✔ Verified for moisture content, viscosity, and chemical composition before production.

2. Production Quality Control

✔ Automated precision manufacturing ensures uniformity and stability.

✔ In-process sampling & real-time monitoring at every stage.

✔ Compliance with GMP (Good Manufacturing Practices) for safety and efficiency.

3. Final Product Testing

✔ Comprehensive lab analysis for viscosity, purity, pH, and gel temperature.

✔ Tested against global standards (USP, EP, JP, GB) for various applications.

✔ Moisture-proof packaging to preserve product quality during storage and transportation.

4. Continuous Improvement

✔ R&D-driven innovation for better formulations and enhanced performance.

✔ Regular third-party audits to maintain compliance with industry regulations.

✔ Customer feedback integration for constant quality optimization.

With our strict quality control measures, we ensure high-performance, reliable HPMC for construction, pharmaceuticals, food, and industrial applications worldwide.

Ready to bring your ideas to life?

Contact us today to schedule a consultation or to learn more about our products.